Hellmann Contract Logistics Invests in New Zealand for Techtronic

7. June 2021Gebrüder Weiss Supports Needy Families During the Corona Crisis

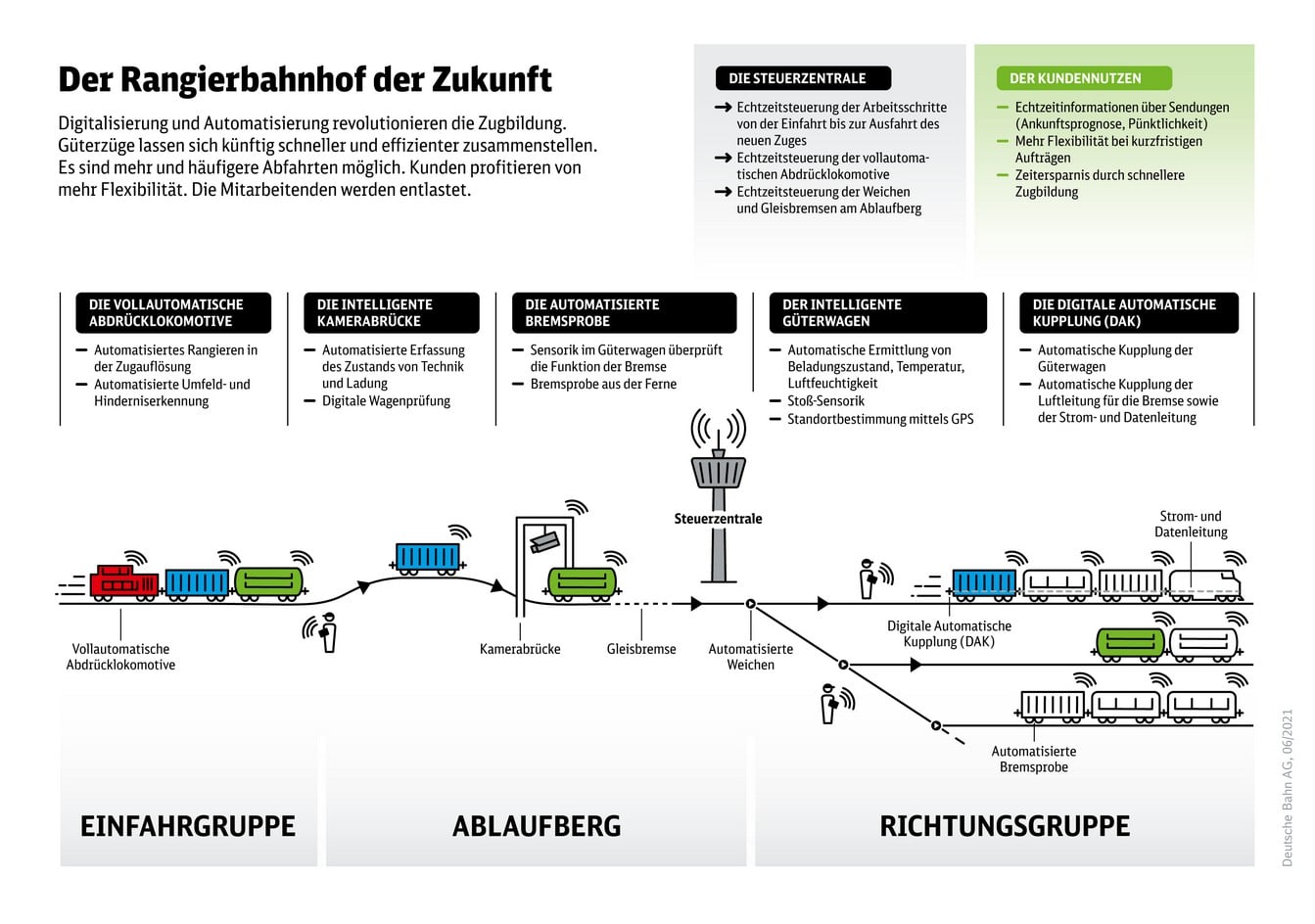

8. June 2021DB Cargo is transforming the Munich-North shunting yard into Germany’s first digital freight station. The BMVI is funding the shunting yard of the future. Customers will benefit from faster and more frequent departures as well as increased flexibility. Employees will be relieved from hard physical work and experience greater safety.

(Mainz/Munich) DB Cargo is making the Munich-North shunting yard Germany’s first digital freight station. The goal is a largely automated train handling process. As a result, the capacity of the shunting yard will increase by up to 40 percent. Freight trains will be able to depart faster, more flexibly, and more frequently in the future. These are crucial prerequisites for more goods on the rail: By 2030, DB Cargo aims to replace 30 million trucks and save 10 million tons of CO2. The Federal Ministry of Transport and Digital Infrastructure (BMVI) is supporting the project with more than 14.5 million euros from the federal program “Future Rail Freight Transport.” DB Cargo is additionally investing around 12 million euros.

Train Handling at a New Level

Federal Minister of Transport Andreas Scheuer: “Where today steel couplings are still connected by hand, brakes and vehicles are checked, and cumbersome shunting is done, intelligent digital technology will automatically take care of this for us tomorrow. Our funding for the Munich shunting yard is groundbreaking. We are accelerating and improving processes. In the future, freight trains can be assembled more efficiently, faster, and more cost-effectively. Because we mean business: More goods on the rail.”DB Board Member for Freight Transport Dr. Sigrid Nikutta: “Digitalization is now bringing significant power to the green rail. DB Cargo has long offered live tracking and online shopping for transports. I am pleased that with the launch of the digital shunting yard, we are elevating train handling to a completely new level. This strengthens single wagon traffic as the backbone of the economy and the competitiveness of rail overall.”DB Cargo is now gradually putting the digital test field in Munich into operation together with partners from industry and science. The innovations benefit both customers and employees: through increased flexibility, faster and more efficient processes, and less physically demanding work.

The Digital Test Field at the Munich-North Shunting Yard:

The Digital Test Field at the Munich-North Shunting Yard:

The Automated Freight Car Diagnosis with Artificial Intelligence (AI)

Today, employees inspect the trains on-site on the tracks for their condition – in all weather conditions. They walk along the trains car by car, which can take over an hour depending on the length of the train. They check whether the cars are damaged, have holes in the side walls, or have bent parts. This can happen, for example, when freight cars are loaded with heavy and bulky goods using large gripping claws. They transmit the results via a tablet into the IT system and also note it on slips of paper in the box on the freight car.In the future, freight trains will pass through a camera bridge that captures images of the individual cars from all sides. Together with the University of Wuppertal, Fresenius University of Applied Sciences, and DB’s AI experts, DB Cargo is developing algorithms that automatically detect and report damage to freight cars. The technology has another advantage: it can also inspect the freight cars from above. In Munich, a camera bridge for these optical tests will be set up in August.

The Automated Brake Test

Before each departure, employees check the brakes: they inspect each axle to see if the brake pads are actually applied and can be released again. Depending on the length of the freight train, this inspection can take up to 50 minutes. That amounts to around 1.2 million brake tests per year. In the future, this will be significantly faster and done remotely: sensors in the freight car will check the function of the brakes and transmit the results digitally.In a joint funding project with the Technical University of Berlin, DB Cargo is testing the first train this year with prototypes of the automated brake test. The goal is to define requirements for a standardized system in collaboration with the Technical Innovation Circle Rail Freight Transport so that the automated brake test can be used throughout Europe.

The Fully Automated Shunting Locomotive

A shunting locomotive is a shunting and pushing locomotive that assembles freight cars into freight trains. In the future, DB Cargo will equip the locomotives with sensor technology that monitors the tracks and the environment, as well as control and regulation technology that manages the drive and brakes.Together with the Technical University of Nuremberg, DB Cargo has already developed a sensor box that perceives the environment like the “human eye” using a video camera, a thermal imaging camera, a laser scanner, and radar. The technology is now being further developed and tested in the Munich-North freight yard until it reaches application maturity. In the future, up to 40 fully automated shunting locomotives are to be deployed at shunting facilities across Germany.

The Digital Automatic Coupler (DAK)

In rail freight transport, screw couplings have been used almost exclusively for over 100 years. To connect cars, employees place a 20 kg heavy hook on the coupling of the next car. The coupling is then tightened by turning a screw thread behind the hook. A Digital Automatic Coupler (DAK) automatically connects freight cars together. It establishes a mechanical connection between the cars without manual labor from employees and couples the air line for the brakes. The DAK also creates the conditions for further automation such as the brake test, as it first provides a stable power supply for the freight cars as well as data lines and connects them automatically. A research project is currently underway, funded by the BMVI with around 13 million euros. Various prototypes of a DAK are being tested nationwide. DB and DB Cargo are involved alongside five other companies. By the end of 2021, a test train equipped with a selected DAK is to be on the move in Europe. The goal is to equip around 500,000 freight cars across Europe with a uniform digital coupling technology.

Photo: © Deutsche Bahn AG / Patrick Kuschfeld / Image Caption: DB Board Member for Freight Transport Dr. Sigrid Nikutta and Federal Minister of Transport Andreas Scheuer