Fraunhofer IIS on “Data Analytics in Spare Parts Logistics”

24. September 2021

DHL Increases Package Prices for Business Customers Starting January 1, 2022

24. September 2021At Arbeitsschutz-Express in Bavarian Leipheim, an automatic storage and order picking system from Kardex will reliably handle the continuously growing order volume in the future. Optimally adapted to the local spatial conditions, the intralogistics expert is implementing a future-proof and highly efficient AutoStore solution with the latest Black Line components.

(PresseBox; Neuburg an der Kammel/Leipheim) Arbeitsschutz-Express is a medium-sized wholesale company that has established itself as one of the German market leaders in e-commerce since 2007 with its website www.arbeitsschutz-express.de. The company offers a unique selling proposition through its wide product variety, high availability, and fast shipping. Both large industrial customers and DIY enthusiasts are supported with customized solutions. The focus of the company is primarily on workwear and safety shoes. These, in particular, pose a special challenge for storage and logistics due to their large packaging.

“In order to continue to supply our customers reliably and quickly, a new, optimized concept for order processing was essential,” says Philipp Wiedemann, Managing Director of Arbeitsschutz-Express. “The best possible utilization of storage space, quick provision of requested items, and minimal failure risk were our most important requirements for the new storage system. Together with the experienced team from Kardex, Arbeitsschutz-Express developed a new solution in the form of an AutoStore system precisely tailored to our needs. The overall package was so convincing that we awarded the contract to Kardex just three months after the first contact.”

Compact, efficient, customized, and future-proof

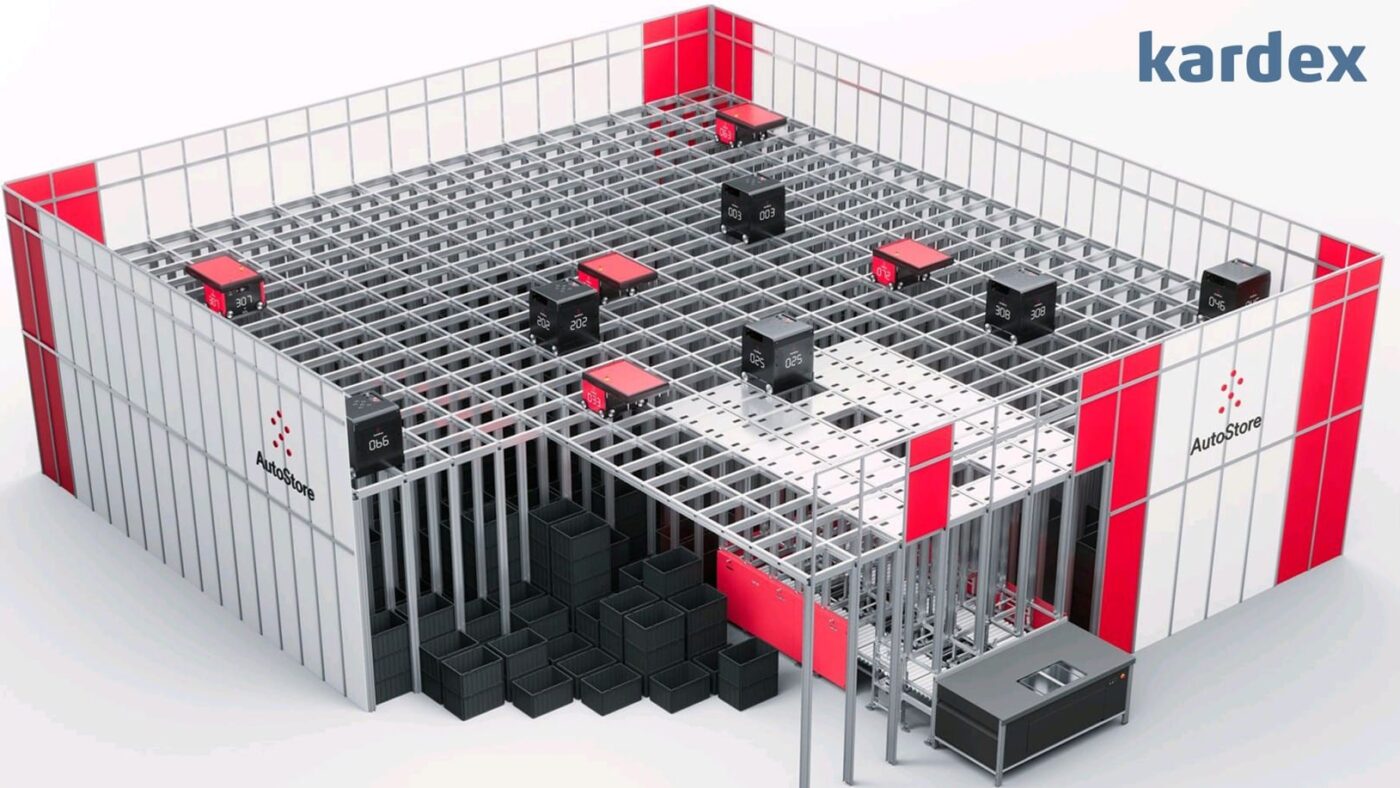

AutoStore systems are characterized by very compact storage, as the containers are stacked on top of each other. Above the container stacks, a rail system (Grid) is mounted, on which intelligent, battery-operated robots move to pick up, sort, and transport the containers to the directly connected workstations (so-called ports) for goods receipt and order picking. The AutoStore containers measuring 449 x 649 mm are available in three heights (220, 330 & 425 mm) and are made of high-quality hard polyethylene.

Highest flexibility and scalability

Shoe boxes are generally labeled on the narrow side – thus, their storage in an AutoStore system only makes sense when placed upright, allowing the requested items to be conveniently scanned before removal. For Arbeitsschutz-Express, 30,000 units of the highest containers will be used in the first expansion stage in conjunction with 26 AutoStore robots of the “Black Line” type (B1). Six carousel ports will be used for the picking and storage of goods and can be switched at the push of a button. Arbeitsschutz-Express can thus coordinate which ports are used for which application at what time according to the processes. Should the performance requirements increase in the future, this can be quickly and easily addressed by the demand-driven introduction of additional robots. Additionally, three frames are planned at the front of the AutoStore system to prepare for future expansion with conveyor ports for goods storage. The system offers a capacity for a total of around 54,000 containers. The warehouse organization is managed through the Kardex MCC Warehouse Management System (WMS), which manages the different storage systems at Arbeitsschutz-Express and optimizes the connecting processes.

“With the investment in an AutoStore solution, we can meet the increased demands in logistics, optimally utilize our available space, and sustainably expand the internal logistics capabilities at our location in Leipheim. We look forward to a strong partnership with Kardex as a basis for long-term success,” Wiedemann continues.

The new AutoStore Black Line

The new AutoStore Black Line complements the Red Line as a product line for requirements with the highest dynamics. With the fully automatic battery change, the Black Line is particularly well-suited for 24/7 operation. The lifting mechanism for the containers is centrally located inside the Black Line robots to transport the containers within the robot housing. This allows for the transport of 425 mm high containers and enables Black Line robots to occupy less space on the grid, allowing for more complex driving patterns and higher speeds. These faster speeds and accelerations can be particularly utilized by the Black Line robots in very large systems with enormous dynamics.

Photo: © Kardex Germany