Goodyear Introduces New Fuelmax Truck Tire Series

27. September 2021

Swiss Cult Drink Vivi Kola Delivered with a CNG-Iveco

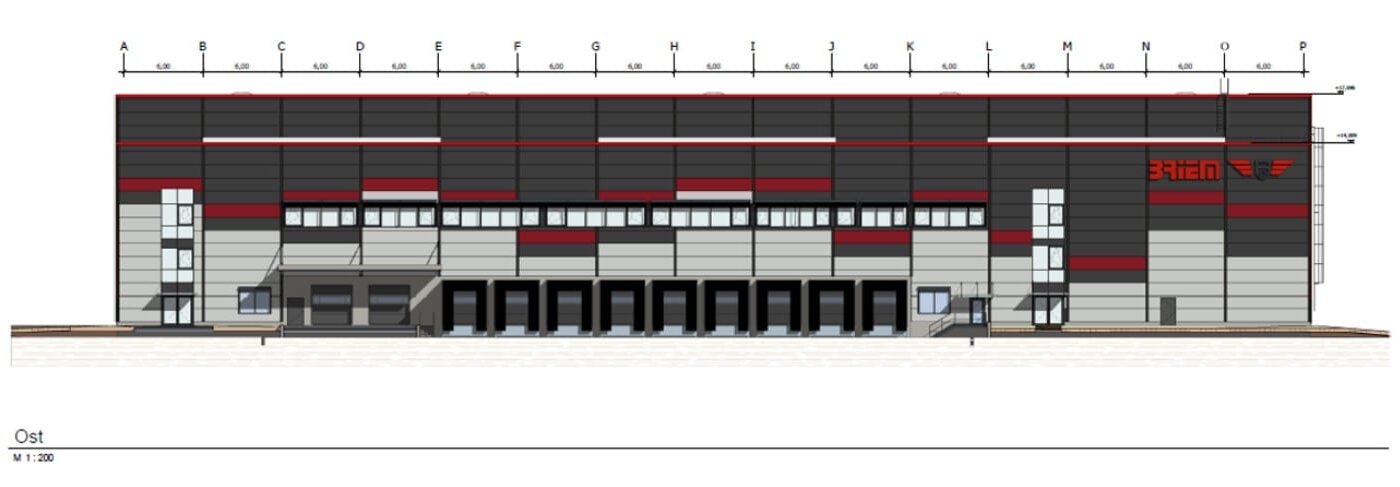

27. September 2021With the commissioning of its new hazardous goods warehouse in Münsingen, Briem Logistics is further advancing the digitalization within its own company. The Filderstadt-based logistics provider relies not only on state-of-the-art technology but also on software solutions specifically developed for the industry. These solutions enable the management and control of all processes involved in complex warehouse management, partially fully – partially semi-automatically.

(PresseBox/Filderstadt-Bonlanden) The new high-bay warehouse encompasses 5,500 storage spaces on a footprint of approximately 10,000 square meters. Briem Logistics expects a monthly turnover of more than 1,500 pallets. The warehouse primarily stores hazardous goods such as plant protection products, pyrotechnics, semiconductors, or their components. Additionally, the new warehouse serves as a logistics center. In Münsingen, deliveries are picked, packed into boxes, and prepared for shipping. The company anticipates around 40,000 boxes leaving the warehouse and distribution center each month.

The safe operation of the warehouse and the reliable execution of all work processes are ensured by software from RETECO Datentechnik. The Lübeck-based logistics software company impressed with its modular system solutions for complex processes. With the expansion of the systems, Briem and RETECO are simultaneously deepening their long-standing partnership. The new components for storage, accounting, and viewing not only build on the existing CARGOBASE® TMS system but also transform it into a standalone platform.

The system consolidates all processes clearly

At the Münsingen site, the new warehouse navigation software from RETECO is of particular importance. It had to be integrated into the Toyota forklift system. This saves time during storage and picking and prevents possible errors in space management. This is achieved by feeding storage space information into the high-bay forklift control, allowing the respective storage spaces to be accessed directly. At the same time, the system calculates the optimal approach angle to the storage locations, thus assisting drivers in their work. The driver only needs to press one button.

The implementation of the system took place over three months. During the integration phase, RETECO’s experts provided on-site support to future users with advice and assistance.

Orders processed faster and more efficiently

After the completion of the joint project, Maximilian Briem, Managing Director of Briem Speditions-GmbH, praises the collaboration with RETECO: “We have personal contacts at RETECO who respond immediately to our inquiries and support us with solutions in case of problems. By implementing the new software components, we can optimize all processes of warehouse management. The new software makes our work more efficient, effective, and productive.”

Michael Reimer, Head of Sales and Marketing at RETECO, is pleased about the intensification of the long-standing business relationship with the logistics specialist Briem: “Once again, RETECO has proven to be a competent partner for sophisticated software solutions for the logistics industry. We are particularly pleased that we were able to deepen our long-standing business relationship with this project.”

Photo: © Briem