spc and ISL on the Importance of Shortsea Shipping for Containers

20. December 2021

Bremen Freight Forwarders Look Positively Towards the New Year

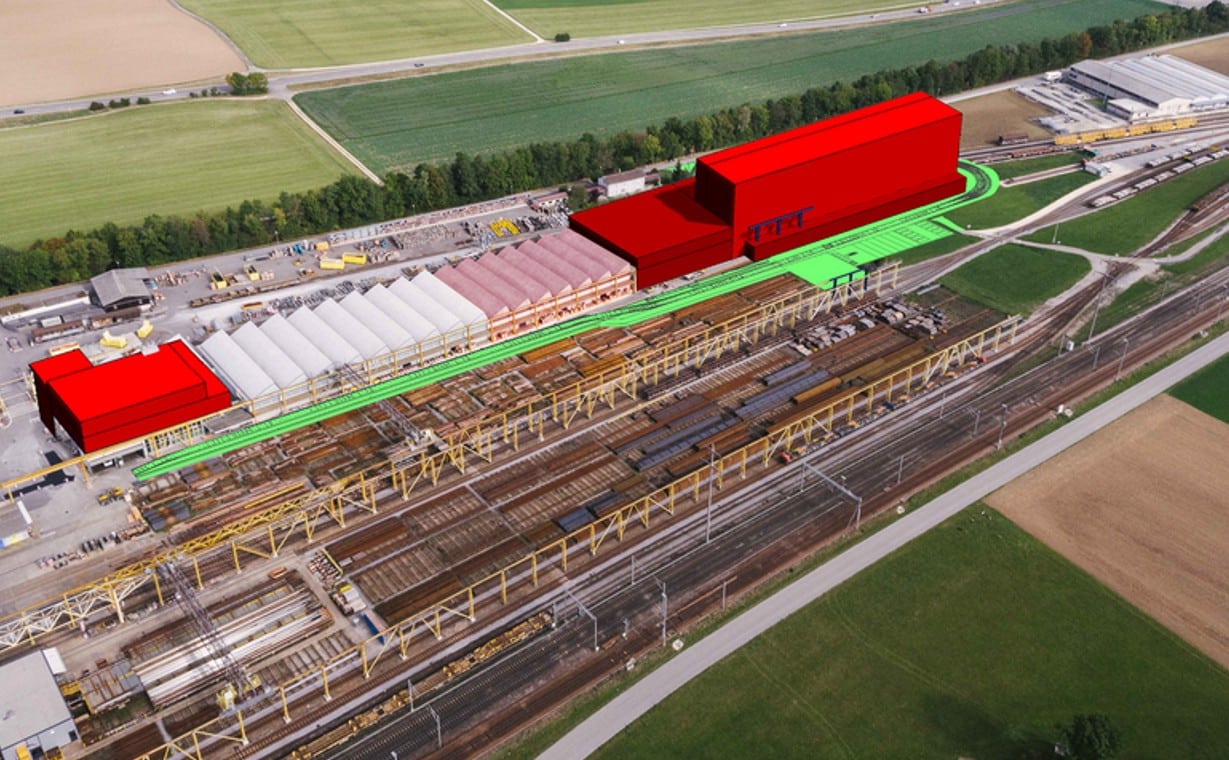

20. December 2021The SBB lays the foundation for the long-term development and modernization of the largest production and storage site for rail technology in Switzerland with the project “Location Concentration in Hägendorf.” Swisslog, an expert in automated storage systems based in Buchs, is realizing an automated high-bay warehouse for the SBB as part of this project, including a picking area and software integration with SAP EWM.

(Buchs/AG) The SBB is expanding its Rail Technology Center into a powerful location for modern rail technology production and central inventory management of raw materials, rail technology components, and spare parts for infrastructure facilities.

To this end, the Aargau automation specialist Swisslog is providing modern high-bay warehouse technology and warehouse management software, focusing on 100 percent system availability and efficient material logistics.

“We are proud as a Swiss company to actively support the Swiss Federal Railways in establishing their new and advanced logistics processes,” says Heinrich Lüthi, Managing Director of Swisslog Switzerland, adding, “Our customer will soon be able to manage their material flows even more efficiently and sophisticatedly.”

Central Supply Facility for Rail Infrastructure Operators

The Rail Technology Center Hägendorf delivers 150 tons of switches, rails, signals, and safety systems for the Swiss rail network annually. The integrated production and logistics site in Hägendorf, with its automated storage systems and the unique manufacturing and assembly facilities specifically designed for switch construction, forms the central backbone for supply security and efficient material supply for troubleshooting, maintenance, and expansion projects of the SBB rail infrastructure.

The continuous availability of the logistics infrastructure is crucial: “We guarantee the SBB nearly one hundred percent availability for all intralogistics components we supply,” emphasizes Heinrich Lüthi, Managing Director of Swisslog Switzerland. To achieve this, the intralogistics company has optimized all layouts so that proven standard components are used in mechanics and control, while complex elements are replaced by simpler ones. Safety is also a top priority. As a measure for active fire prevention, the logistics are encapsulated and inerted by the supply of nitrogen.

Optimized Layouts with SAP EWM

The high-bay warehouse planned by Swisslog is to be built with approximately 13,800 pallet spaces, designed with three aisles, and operated with three Vectura brand stacker cranes. The cassette warehouse, specifically designed for long goods, is single-aisle and offers storage capacity for 1,570 spaces. Swisslog is implementing the SAP EWM system (Extended Warehouse Management) not only in the new automated storage areas and picking zones but also connecting existing facilities, such as manual indoor and outdoor storage, to the software platform. Go-live is scheduled for summer 2023.

Photo: © SBB