Supply Chain Security and Cost Pressure are Currently a Priority

18. July 2022

trans-o-flex wins the EURODIS Award for Best Quality

19. July 2022The Körber Business Area Supply Chain was established 10 years ago and emerged from the merger of 12 individual companies into a common brand. Körber keeps supply chains running and offers solutions related to intralogistics. Even after COVID-19, the demand for automation in intralogistics remains, although the conditions have become more challenging.

(Hamburg) Keeping supply chains in motion is the core competence of the Körber Business Area Supply Chain. And never has this topic been more relevant than in these times. Automation in logistics, especially in intralogistics, has become a key issue. A trend that began with the advent of e-commerce and has accelerated dramatically due to the COVID-19 pandemic.

Demand Remains High, but Customers Are Uncertain

The war in Ukraine and the associated rise in raw material prices and subsequent inflation have somewhat dampened the boom. Dirk Hejnal, CEO of the Körber Business Area Supply Chain, notes: “While the high demand for automation continues, customers are uncertain due to the current developments. No one can currently predict price trends.” Hejnal sees no major problems in completing ongoing projects, but there are significant uncertainties among customers regarding new construction projects.

Sourcing Becomes a Challenge

Overall, the situation in intralogistics is very difficult. “The renewed lockdowns in China are causing significant delays in deliveries. But due to the war in Ukraine, sourcing raw materials has become a real challenge. Much material, such as components, but especially steel, has come from Ukraine and Russia. We had to turn to other countries and regions and purchase at significantly higher prices.”

In sourcing, there is now a greater focus on a regional procurement strategy, but the markets are currently volatile. All of this also means that Körber must prepare for margin losses. In addition to higher purchasing prices, Hejnal also expects higher wages due to inflation.

Broad Range of Solutions

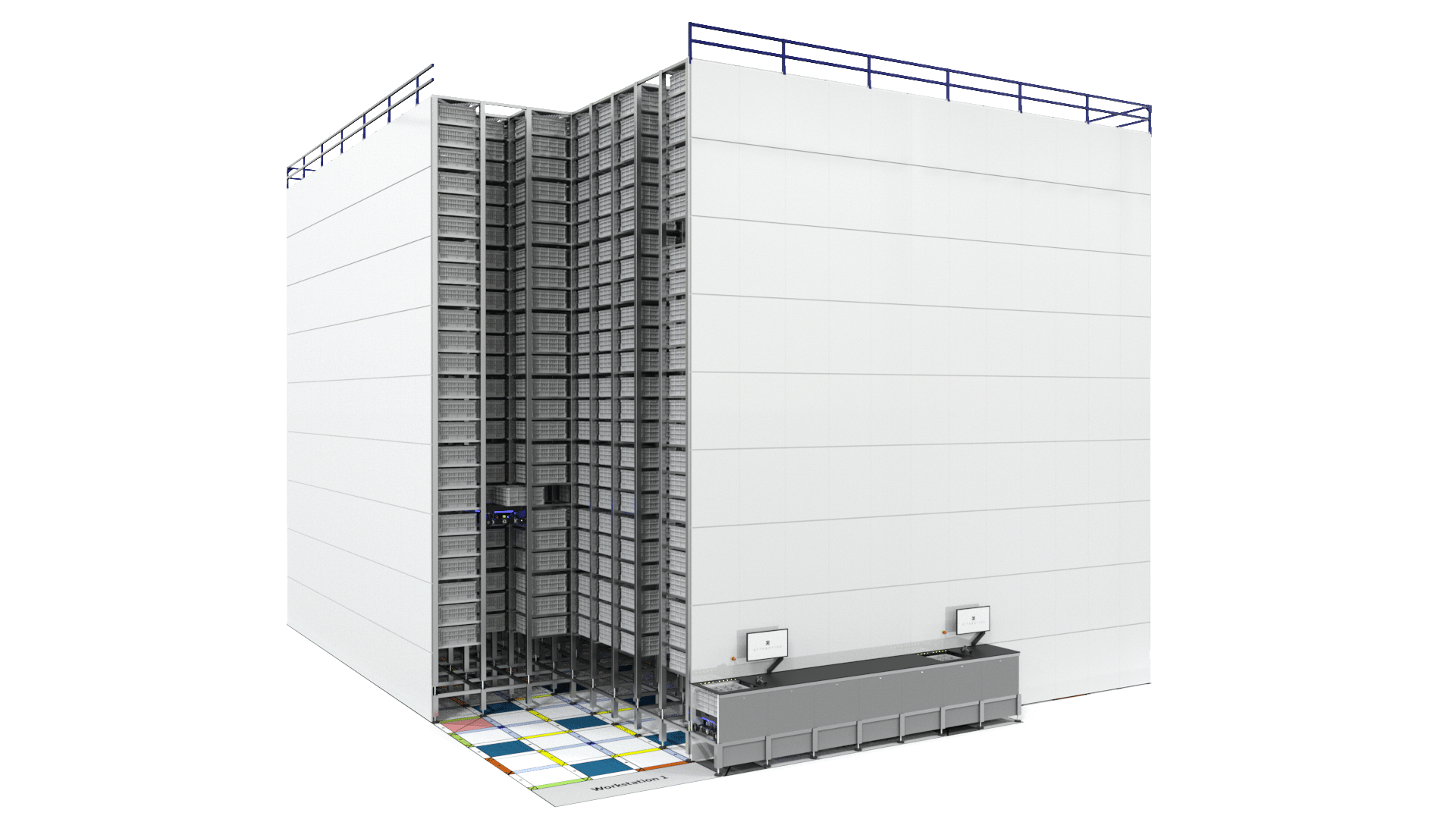

Shuttle vehicles like this operate on tracks that run perpendicular to storage aisles and transport satellite or load units.

Shuttle vehicles like this operate on tracks that run perpendicular to storage aisles and transport satellite or load units.

The globally active Körber Business Area Supply Chain is well-positioned in intralogistics. Technologies for all requirements are offered. Körber provides solutions in software, automation, and conveyor technology and can connect these components as a general contractor.

“Our offerings are in demand wherever intralogistics is being automated. Whether it’s about new builds or retrofitting, we can help,” describes Hejnal the competencies. The main customers currently come from the areas of cold chain, retail, fast-moving consumer goods (FMCG), as well as food and beverages.

Presentation at LogiMAT

Earlier this month, the Körber Business Area Supply Chain presented itself at the intralogistics trade fair “LogiMAT 2022” in Stuttgart, showcasing a new shuttle system and the “Operator-Eye Technology,” which uses AI to prevent errors in fully automated order picking.

The “Operator-Eye” is integrated to prevent errors in fully automated order picking in the depalletizing system.

The “Operator-Eye” is integrated to prevent errors in fully automated order picking in the depalletizing system.

“LogiMAT is the most important trade fair for us in Europe. Even though we have positioned ourselves well digitally during the pandemic, and that will continue, it was nice to meet customers and partners in person again,” Hejnal reflects on the event with satisfaction.

Also in Stuttgart, the company announced a strategic partnership with the Canadian robotics company Attabotics. Körber will support Attabotics in the European market. The young company is already successfully operating in the USA and Canada.

Attabotics replaces the rows and aisles of traditional fulfillment centers with a space-saving grid structure with robotic shuttles.

Attabotics replaces the rows and aisles of traditional fulfillment centers with a space-saving grid structure with robotic shuttles.

About Körber Business Area Supply Chain

The challenges along the supply chain are growing daily. Körber uniquely offers a wide range of proven end-to-end technologies for logistics – for every company size, business, or growth strategy. The service portfolio includes software, automation solutions, voice, robotics, and transport systems – and combines the expertise for comprehensive system integration under one roof. As a global partner, we meet today’s challenges as well as the ever-changing requirements in logistics. “Conquer supply chain complexity” – with Körber. The Business Area Supply Chain is part of the international technology group Körber.

Photos: © Körber Business Area Supply Chain

Since 2019, Dirk Hejnal, 56, has been leading one of the largest units of the international technology group Körber – the Business Area Supply Chain, with more than 2,600 employees.

The business economist has a long-standing industrial background. Before his time at Körber, Hejnal was responsible for the Land Technology and Food Solutions divisions at GEA Group, a specialist in process and plant engineering. Hejnal was also a co-founder of a start-up in the AGOR Group, a member of the management board of the Capri-Sun Group, and managing director of Pouch Partners, a manufacturer of beverage processing and filling machines as well as packaging materials. All of this has sharpened his perspective on global supply chain management and the added value of digital technologies.