Fiege with Independent Power Supply in Gengenbach

13. August 2022

Fraunhofer IML Investigates Energy Efficiency of Logistics Locations

16. August 2022IDG Sealing Technology GmbH, an expert in modern sealing profiles and materials based in Kirchheim unter Teck, is restructuring its logistics. Founded in 1971, the company plans to enter automation at its new location in Albershausen and has commissioned Jungheinrich to build a single-aisle automated storage and retrieval system (ASRS).

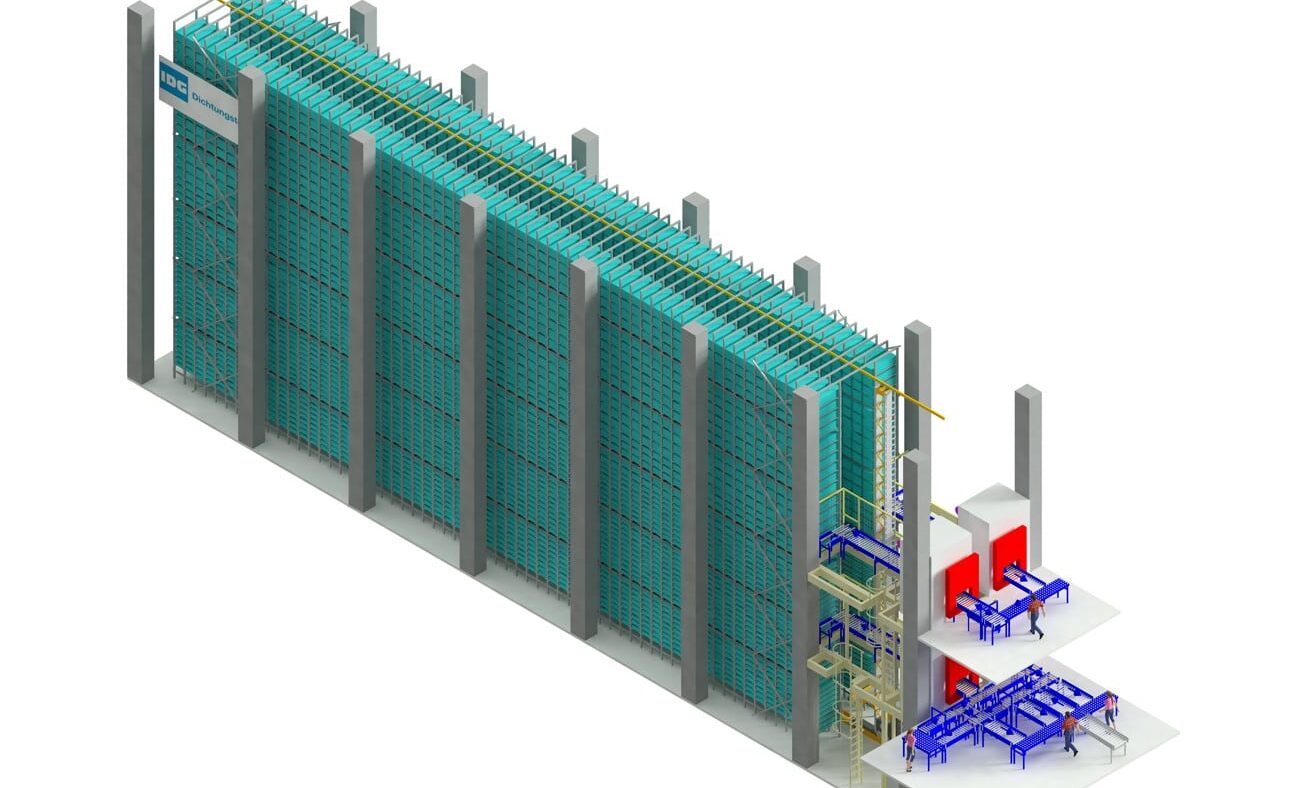

(Hamburg/Albershausen) Until now, IDG Sealing Technology has organized its material flow exclusively manually. Due to strong growth, the company from Baden-Württemberg needs to expand its logistics and is seizing the opportunity to switch to automated processes with the new construction. “The strategic decision for automation represents an important milestone for IDG Sealing Technology, which we will closely accompany from planning to turnkey handover, including extensive training,” reports Knut Schröder, Sales Project Manager ASRS at Jungheinrich. “IDG Sealing Technology benefits from structured workflows, ergonomic workplaces, high transparency, and compact storage density with optimal capacity utilization on a small footprint.” The 37 m long, 8 m wide, and 15.4 m high ASRS offers 11,562 storage locations, resulting in a 1.5-fold increase in performance compared to the current situation.

Conveyor Technology to the Pre-Zone Building

The new ASRS, where containers are stored double-deep, will be connected to the pre-zone building for assembly supply via conveyor technology. The ground floor is designed for two picking stations and one for goods receipt, with another picking workstation located on the upper floor. In the future, work will be conducted here on five working days in a single-shift operation. For this, Jungheinrich will supply the STC stacker crane including control and visualization. This allows for the storage and retrieval of 150 containers per hour. Additionally, the delivery includes the rack steel construction, container conveyor technology, platform systems, four gates with eight high-speed doors, and four fire protection doors. The Hamburg-based company will also handle the electrification and the connection of the customer’s ERP system to the also ordered Jungheinrich WMS.

Fire Protection Concept Adjusted

Since the customer designs the system with inerting – that is, with oxygen reduction as a preventive fire protection measure that requires a particularly tight building envelope – Jungheinrich has adjusted its fire protection concept: Instead of the usual sprinkler systems, the gates with high-speed doors will be used. Jungheinrich also demonstrates flexibility and customer orientation with two other structural features: For the waterproof concrete floor slab, the Hamburg-based company uses special injection anchors, and the ASRS will not be installed through a wall opening as is usually the case. Since the oxygen-reduced atmosphere requires a construction without skylights, Jungheinrich will bring all ASRS components into the building during the construction phase through the only remaining opening in the roof.

Further Collaboration on the Horizon

“The chemistry has been right from the start,” says Aron Olbrich, Managing Director of IDG Sealing Technology GmbH. “Even in the bidding phase, the cooperation proved successful, as Jungheinrich has significantly advanced the project with important impulses.” The ASRS is the first collaboration between Jungheinrich and IDG Sealing Technology – but further projects are already foreseeable: The expansion of the warehouse with an additional aisle and picking workstations is already planned, with the technology accordingly designed. The two partners will also jointly support the now automated intralogistics of IDG Sealing Technology through the service contract in the future.

Photo: © Jungheinrich