Garbe Industrial Real Estate Acquires Brownfield in Salzgitter

28. August 2022

Swiss Post presents its new parcel center in Buchs

28. August 2022Sonepar in Switzerland is taking its efficient logistics to the next level by investing in a robotic order picking system. Within the global group of the same name, they are now pioneers. In the future, a Robotics Pick & Pack solution from Kardex will fully automate the processing of small orders and elevate the performance and cost-effectiveness of Sonepar’s AutoStore facility to a new level.

(Zurich) As a leading electrical wholesaler, Sonepar Suisse AG offers customers from trades, commerce, and industry a vast selection of high-quality electrical products and materials for their daily needs. Sonepar distributes more than 220,000 products through its own webshop, promising to deliver orders within 24 hours.

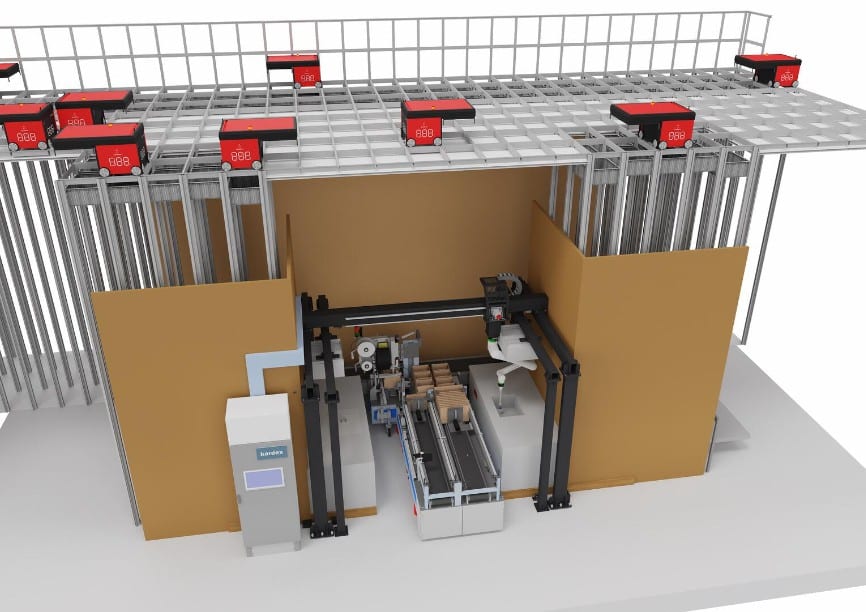

In 2020, the new Central Distribution Center was put into operation. After a two-year construction phase, the first wooden high-bay warehouse in Switzerland now stands in Wallisellen. A powerful AutoStore system was already integrated during construction. As the first company in the globally operating group, Sonepar has now invested in the first robotic order picking system in Switzerland. This has optimized order processing for current tasks and has best prepared the company for future market demands. In the AutoStore system, small parts are stored in approximately 55,000 containers, which are provided by battery-powered robots on a per-order basis at the AutoStore workstations, known as Carousel Ports. Until now, order picking at these ports has been done manually at Sonepar.

“Investments in our supply chain are always a win for our customers. With automated and digital processes, we increase our quality while saving time in order processing, allowing us to provide even better service,” says Benjamin Ertl, Head of Supply Chain at Sonepar Suisse AG. “Our Central Distribution Center is already an undeniable success story in terms of sustainability and automation. We have assessed the Pick & Pack robotic system from Kardex as the ideal overall solution. The project is in execution, with the start of real operations planned for Q1 2023. After nearly five years of intensive discussions and planning about robots in order picking, a dream is coming true for us.”

Fully Automated Precise Picking with 3D Vision

The overall solution being integrated by Kardex into the existing processes at Sonepar in Switzerland includes a Robomotive portal robot that serves two Carousel Ports in parallel by fully automatically picking items from the AutoStore containers and placing them into order boxes. Using 3D vision cameras and intelligent software algorithms, the pick-and-place robot replicates the precision and synchronization of human hand-eye coordination. Thus, it is capable of handling items of various shapes and sizes without master data or teach-in processes. The “Auto-Learning” function ensures that new items can be handled efficiently. Furthermore, it enables continuous optimization of operational processes.

An integral part of the overall solution is also a packaging machine that erects, provides, seals, labels, and feeds cartons into the existing material flow towards the shipping area. Throughput rates of over 300 picks per hour are achieved.

Designed for 24/7 Operation

In 2020, Kardex acquired a majority stake in the Dutch company Robomotive, which has specialized in the development of smart robotic technologies since its founding in 2011. Since then, the intralogistics expert and global AutoStore partner Kardex has been able to offer fully integrated robotic solutions from a single source for automatic picking in the item pick and full case areas.

Robot cells can be easily integrated into AutoStore systems, enabling previously unimaginable performance. They can operate 24/7 as needed – a crucial component in a time when customers place orders around the clock from all parts of the world. The advanced features of the pick-and-place robots allow for handling a diverse and constantly changing product range. They work with various AutoStore processes, including pick-to-tote, pick-to-belt, pick-to-pallet, consolidation, and replenishment, and can be integrated into different storage systems, sorting systems, and packaging machines. The innovative technology consisting of 3D cameras, flexible mechanical grippers, and intelligent software algorithms enables precise recognition, localization, gripping, and placement of unknown, randomly arranged items, even in segmented containers.

All business processes and material flows are fully transparent. Robotic applications enable 100% digitized workflows and significantly improve the quality and reliability of logistics processes.

Photo: © Kardex