CLAAS and Hellmann Expand Strategic Collaboration

19. September 2022

DEKRA develops workplace health promotion for truck drivers

19. September 2022“Well prepared for demand peaks”: As a result of ongoing expansion, the Swiss mail order company has decided to technically optimize its logistics processes at the Schenkon (LU) location. The choice fell on an AutoStore system, which can handle both online and catalog as well as retail business. The remarkable thing about it: An existing building was raised by 2 floors, and the robotic system was installed directly under the roof.

(Buchs, CH) Lehner Versand, the Swiss mail order company with over 39 years of tradition, has achieved something special: At its headquarters in Schenkon/Sursee, Canton of Lucerne, it has equipped the existing warehouse building with a new, highly modern robotic warehouse – and not next door, but on top. As part of the expansion project “Skyscraper”, the business has grown by a fifth and sixth floor. The entire facade of the extension has been equipped with solar panels. The project was led by Lehner Versand and supported by the external logistics consultant MWL.

Lehner Versand AG is one of the largest mail order companies in Switzerland. The company offers its customers a wide range of products including bedding, bed linen, shoes, garden furniture, fashion, workwear, perfume, and household appliances. The entire range of more than 50,000 different items is available in the online shop. A large part of it can also be obtained in one of the 9 branches.

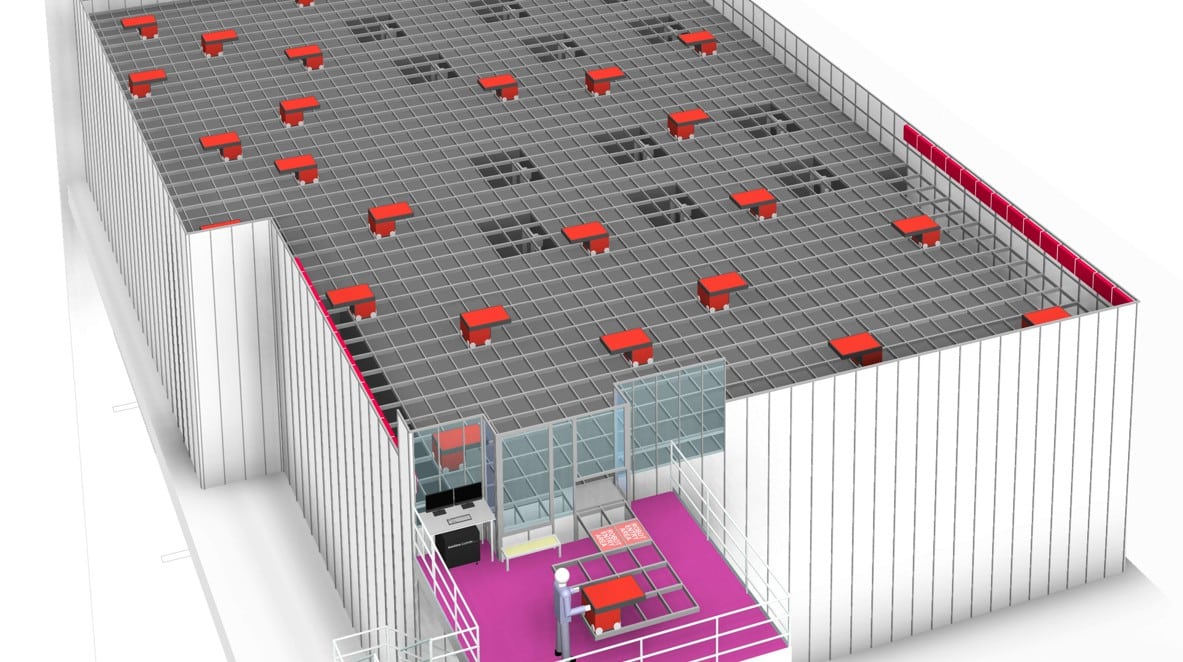

Not directly accessible to customers, but viewable, is fully automated technology in the two top newly built floors at the headquarters in Schenkon: An AutoStore system, in which Lehner products are stored and can be immediately picked according to order on demand.

Over 300 AutoStore projects implemented worldwide

“AutoStore is a well-established and cross-industry automated system for small parts in warehouse logistics,” describes Heinrich Lüthi, Managing Director of Swisslog Switzerland, the executing logistics company. Why the Aargau company received the order from the mail order house is emphasized by Michael Hirschi, Head of Logistics at Lehner: “From the very beginning, we had great confidence because Swisslog has successfully implemented the most AutoStore systems worldwide and is clearly the leader in Switzerland for this type of logistics automation.” Hirschi adds: “And so our planning and installation also went smoothly and quickly.”

Compact warehouse with 20,000 containers

The principle of AutoStore is based on a cube in which containers with goods stand “close together” next to and above each other in designated shafts. The expert refers to it as a “compact warehouse”. The solution for Lehner includes 20,000 containers for around 25,000 products. On the top of the warehouse, robotic vehicles run on rails, totaling 27 at Lehner, which software-controlled store and retrieve these containers or supply them to picking workstations via lifts. The latter are located one floor below. At these workstations, one employee is responsible for taking the goods of an order from a storage box and preparing them either for shipping or for pickup at the retail branch. The storage container then automatically returns via the lift to the cube, where it is re-sorted by a robot.

Future-proof thanks to expandability

Lehner initially ordered five picking stations. “However, there is always the possibility to add seven more,” says Lüthi from Swisslog, pointing out that the investment in the new technology is particularly future-proof. “Lehner benefits from the ongoing e-commerce boom, and we are very pleased to support the growth of the Swiss mail order house with our technology. It is part of a forward-looking concept to plan buffers for further expansion.” The capacity of the current system is also expandable by deploying more robots if needed. “Thanks to these optional expansions, we are very flexible,” says Michael Hirschi from Lehner, “if the business fluctuates or we face demand peaks, we are well prepared with our new dynamic logistics system.”

Photo: © Swisslog