Logistics Arts Production with Processes for Pallets Made from Wood Waste

10. March 2023

Successful Start: Panattoni with a Strong Beginning to the Year

14. March 2023Thanks to improved planning options in goods receipt, trucks no longer have to wait and can be unloaded directly. The cloud-based software solution reduces personnel and process costs through more efficient information management.

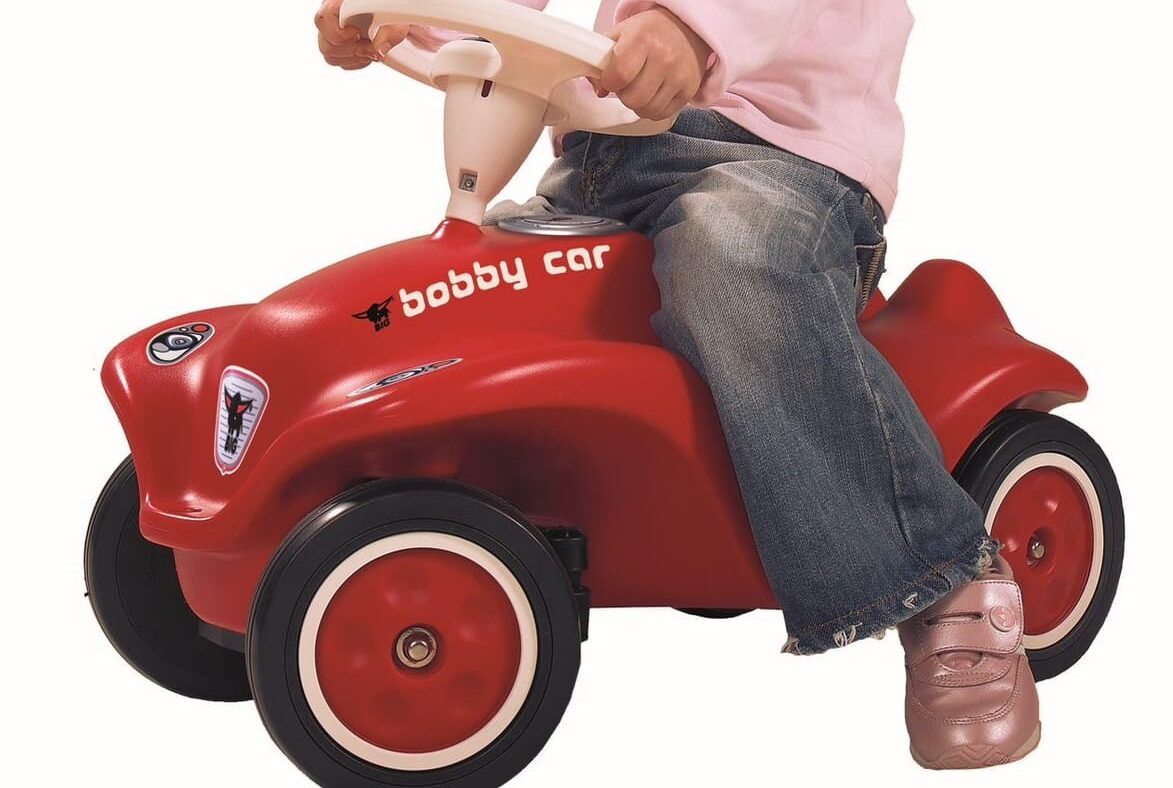

(Freiburg) Whether it’s the famous bright red Bobbycar from Big, wooden trains from Eichhorn, or lifelike baby dolls from Corolle: under the umbrella of the Simba-Dickie Group, numerous well-known toy brands come together. A part of the toys from the company group, which is headquartered in Fürth, is distributed to retailers via the Simba-Dickie central warehouse in Sonneberg, Thuringia. To further optimize the processes at the ramp and reduce waiting times for truck drivers, the company recently introduced the cloud-based time slot management system SLOT from the Freiburg software house Cargoclix at this location. Since then, around six to ten trucks are processed daily in goods receipt via the software.

“Before the introduction, waiting times for trucks could be up to two hours, as deliveries were not announced and all unloading capacities were often exhausted,” reports Sven Jakob, Senior Logistics Manager at Simba-Dickie. The system now usually guarantees direct unloading, as personnel deployment can be planned and organized appropriately the day before. Those wishing to book a time slot for delivery at Simba-Dickie in Sonneberg can do so with a lead time of 120 days. Short-term reservations are also possible – until the day before at 10 a.m.

The fee of 50 cents charged per booked time slot is covered by the Simba-Dickie Group and is not passed on to the logistics service providers. “The rationale is that the process costs and the time savings now possible completely offset the low booking costs,” explains Sven Jakob.

As reasons for choosing the Cargoclix system, the Senior Logistics Manager cites the user-friendliness of the tool, the brand recognition of Cargoclix among freight forwarders and carriers, as well as the low ongoing costs of the application. “The introduction of SLOT was accepted by all logistics service providers from the very beginning,” he explains. He sees the greatest advantages of the system in reduced effort due to more efficient information transfer, the simplification and automation of the registration process, and better planning of time slots for unloading. Furthermore, earlier and more flexible coordination of deliveries with service providers is now possible.

In addition to the central warehouse in Sonneberg, the Simba-Dickie Group also operates warehouses in Burghaslach and Lam. Additional warehouses abroad are located with the national subsidiaries in Bulgaria, Czech Republic, Netherlands, Spain, France, Hungary, Italy, Poland, England, Norway, Ukraine, United Arab Emirates, Qatar, South Africa, and Turkey.

Photo: © Simba-Dickie Group