The “GAS 95” from HGK Operates Emission-Low on the Rhine

9. February 2024

Recruitment: “The best eleven are not always the best eleven!”

9. February 2024Author Alexander Edelmann identifies seven software trends for an efficient supply chain in 2024. Digitalization, real-time data, artificial intelligence, and platform connectivity play a key role in implementation.

By: Alexander Edelmann

(Gütersloh) Breaking down data silos, strengthening sustainability in warehouses, and improving customer experience along the supply chain: These goals are the focus of logistics and industry in 2024. The key to implementation lies in the digitalization of the supply chain and real-time collaboration. With these seven trends, companies are shaping their supply chains intelligently and minimizing risks.

-

Collaborative platforms replace silo thinking

From isolation to networking: Many companies use rigid IT structures that have developed over the years. Due to a lack of interfaces, ERP island solutions cannot communicate with other software systems. The weaknesses of ERP silos became particularly evident during the Corona crisis and the stalled supply chains. The use of many different software systems introduces sources of error, slows down the flow of information, and incurs high costs for maintenance and updates. The effort increases, as do service costs. Therefore, companies are increasingly breaking down silos. They rely on collaborative network platforms that map supply chain processes across departments and companies, allowing all stakeholders to coordinate better in a shorter time. IT solutions with REST APIs – maximally flexible, open interfaces – enable collaborative work with simple real-time data transfer. These REST APIs are universally accessible and can easily connect many different applications.

-

Holistic consideration of goods flows reduces errors

Fragile international supply chains lead to geopolitical and economic challenges. Many companies are already making their supply chains more flexible and robust – with a mix of global and regional value chains. Even if production under re- or nearshoring conditions may be slightly more expensive, the supply chains become significantly more stable. To remain profitable, companies should continuously optimize their purchasing and procurement processes as well as their supply chain management. A strengthened network between companies, suppliers, buyers, manufacturers, and traders is becoming increasingly important for efficient collaboration. Industry pioneers use software tools to securely exchange data in real-time and support workflows for forecasting, production, delivery, inventory, and capacity. This improves data flow and allows for a more holistic view of goods flows. The result: errors, delays, and inefficiencies are reduced in the long term. This lowers costs for companies while simultaneously strengthening their competitiveness.

-

Improved responsiveness in the supply chain

Transparency and collaboration are central factors for a resilient supply chain: Decision-makers can immediately see if a particular area of the supply chain is affected by a current event and can respond more quickly. Due to the volatile economic situation, many companies demand flexibility in processes when searching for suitable IT software. To better plan and scale the supply chain, trustful collaboration among all stakeholders is crucial. New communication platforms share all relevant data on a single interface, consolidate agreements, and support quick decisions in response to dynamic demand fluctuations. Thus, such AI-supported tools provide a clear competitive advantage over the traditional use of spreadsheets or emails. All parties involved in the supply chain have access to the data – depending on their function with different permission groups. This improves the responsiveness of the supply chain.

-

Smart asset tracking enhances customer experience

Track & Trace enables efficient operations and improves inventory management. Real-time tracking systems monitor goods along the supply chain and can display this information at any desired time – on both small and large scales. Next-generation software solutions collect and centralize this real-time data and link the information clusters across the board. With smart tracking, companies receive current, decision-relevant information, allowing them to fully leverage data potential and further optimize their supply chain. This increases operational efficiency, enriches the customer experience across all channels, and simplifies compliance and regulatory management. Through improved order processing and traceability of goods, companies can better tailor their products to their customers.

-

Using AI for precise inventory monitoring

The European Green Deal calls for the reduction of greenhouse gas emissions. To achieve this goal, product traceability is crucial. Companies are therefore relying on precise inventory monitoring along the entire supply chain. AI-based software systems support this by recognizing patterns, deviations, and bottlenecks in the supply chain through comprehensive data analysis. This leads to more effective planning, minimizes unnecessary transport, and reduces the ecological footprint, as products reach consumers faster and more efficiently. At the same time, companies can better manage their inventory, reduce overstock, and utilize warehouse resources efficiently.

-

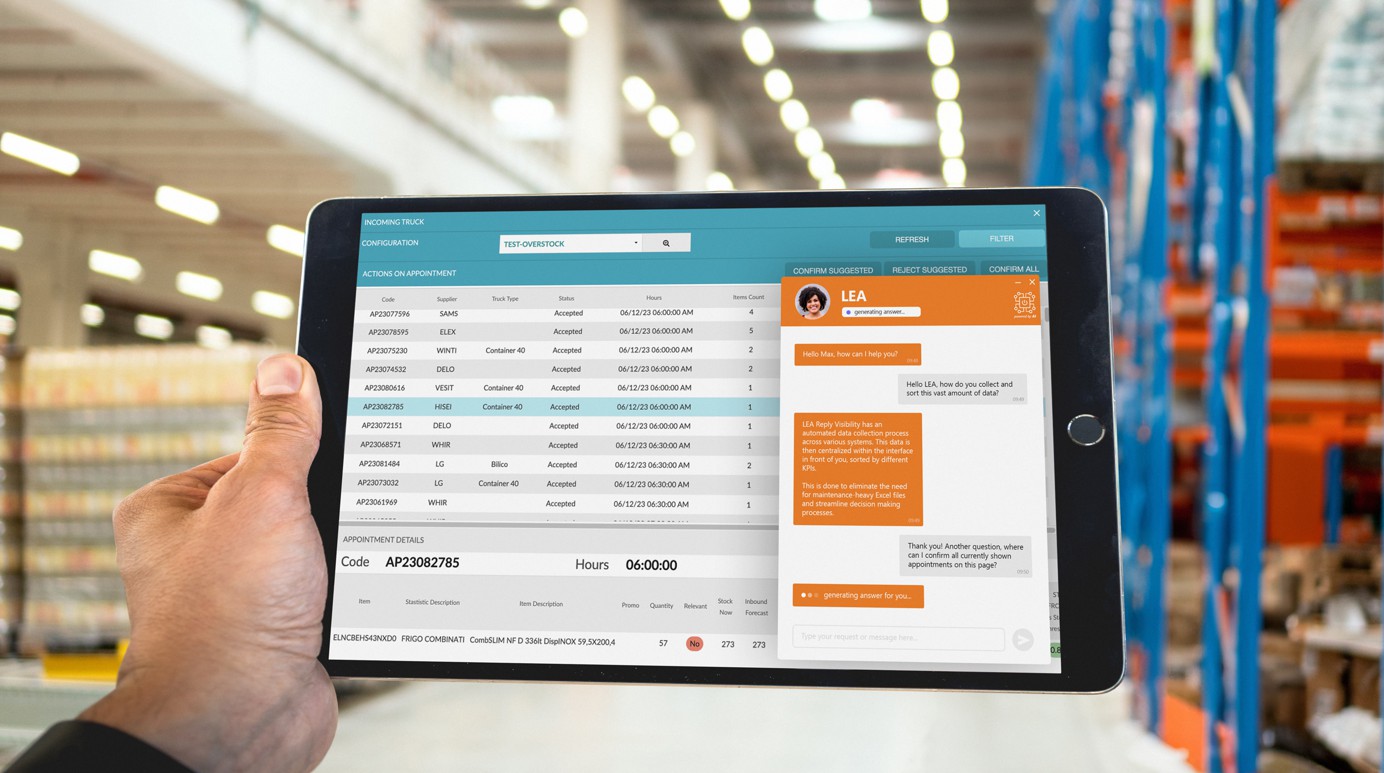

Improved WMS handling with AI

With AI-supported warehouse management systems, companies can process and analyze large amounts of data in real-time. Automated decision-making processes ensure efficient use of resources such as warehouse space, personnel, and equipment. To simplify the use of the WMS, it is advisable to integrate an AI chatbot into the overarching platform that assists employees in their daily work. Such a module works bidirectionally: The bot provides precise and quick answers to questions about products, processes, and system workflows without employees having to search for long. This increases efficiency in daily operations and saves time. An AI-based WMS thus enhances flexibility and makes warehouse management and logistics quickly scalable depending on the economic situation. This leads to improved competitiveness and customer satisfaction in the long term.

-

Gen Z workforce expects digital workflows

By 2030, 76 percent of German employees will be digital natives. They expect a high affinity for technology from their employers. To attract this workforce and counteract the shortage of skilled workers in logistics, companies must proactively invest in a digital environment. In addition to robotic processes and automation in the warehouse, logistics providers can also rely on AI, IoT, voice recognition, and wearables. AI reads data, analyzes order processing, and tracks products – in real-time. This significantly shortens process times, allowing employees to focus on other value-adding, more interesting tasks.

Conclusion

In 2024, industry leaders will continue to automate their processes, achieving efficiency gains. They leverage the advantages of AI – from prescriptive analytics to collaborative robots to intelligent chatbots – to manage the supply chain from A to Z quickly and efficiently. With the right IT software solution, companies achieve an agile workflow in a complex supply chain and develop it further in a risk-reduced, innovative, and intelligent manner. This ultimately also counters the shortage of skilled workers.

Alexander Edelmann is an Associate Partner at Logistics Reply. Logistics Reply offers state-of-the-art software solutions that enable companies to build an efficient and highly connected digital supply chain, where various systems, partners, people, and machines harmoniously interact through the use of the latest technologies such as artificial intelligence, robotics, wearables, and IoT. Logistics Reply supports its clients on their transformation journey and guarantees a fast time-to-value and long-term quality results thanks to its more than 20 years of experience and in-depth knowledge of supply chain technologies and processes. Logistics Reply is a company of the Reply Group. www.leareply.de

Photos: © Logistics Reply