KION Group Triples Dividend for 2023 Results

1. June 2024

Schuon relies on HVO fuel for customer Saint-Gobain

4. June 2024Postal and logistics processes depend on a multitude of factors that are beyond the control of the service provider. At the same time, customer demands for delivery speed have never been higher. Maintaining service levels during operational disruptions is therefore a constant challenge, especially when one does not know what will happen next. Consequently, companies are looking for tools that reduce uncertainty and support emergency planning.

Von: Alexandra Ballestrem und Roosmarijn Schopman

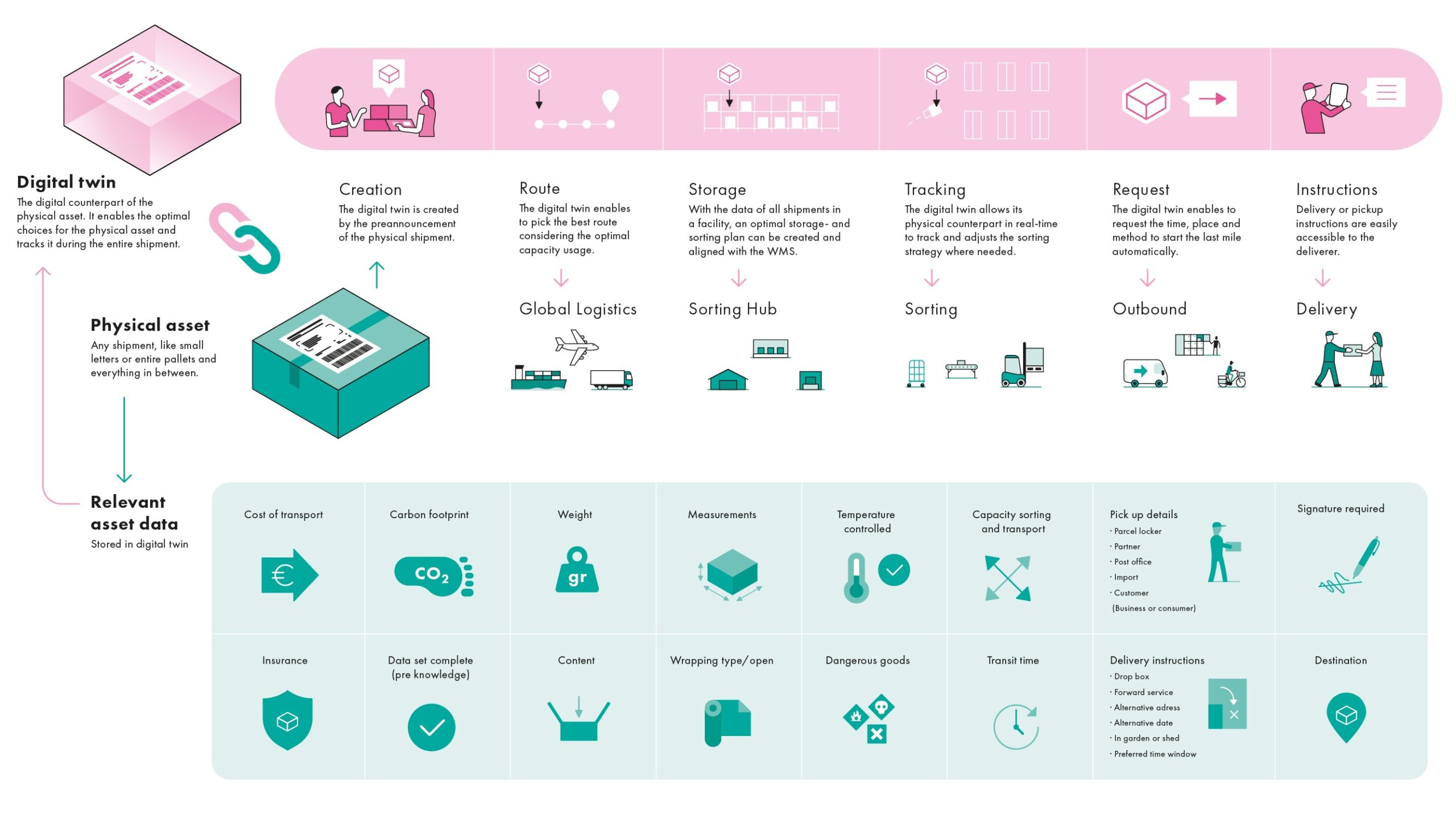

(Delft) Mature logistics processes are highly automated. When packages or letters pass through a sorting center, they are photographed, scanned, and tracked with a variety of devices. This generates vast amounts of data that can be stored and analyzed to make operations transparent. More and more postal and logistics companies are utilizing these data streams to create “digital twins.”

A digital twin is a virtual representation of a physical object or, in this case, a process. By feeding real data into customized mathematical models that accurately reflect operational workflows, it is possible to simulate how changed parameters will affect the company. Since the data required for the system’s operation is already available through existing automation equipment, the digital twin allows for virtually unlimited and nearly risk-free experimentation. While the digital twin does not predict the future, it enables effective emergency planning and potential optimizations.

Emergency Planning for All Scenarios

Emergency Planning for All Scenarios

For example, consider an increase in package or letter volume: Are the existing processes flexible enough for the current facilities to handle the higher volume without issues? If not, are investments in a new sorting center, facilities, or personnel necessary? Companies with a digital twin can input the increased package and letter volume into the models and test the processes to answer these questions. A new sorting center takes at least five years to break even. Therefore, data-driven systems are of immense value for decision-making.

Unforeseen outages are another event that can be modeled by the digital twin and mitigated in their impacts. What happens if one of the 20 to 80 national postal centers (depending on the size of the country) fails? This can be simulated in the digital twin to observe the effects. Additionally, the simulation allows for proactive planning and strategy to minimize downtime and delivery delays in case of emergencies. This way, the best routes can be determined in advance to distribute the volume and keep the impacts manageable, rather than conducting time-consuming analyses after an event has occurred.

How the Virtual World Influences the Physical World

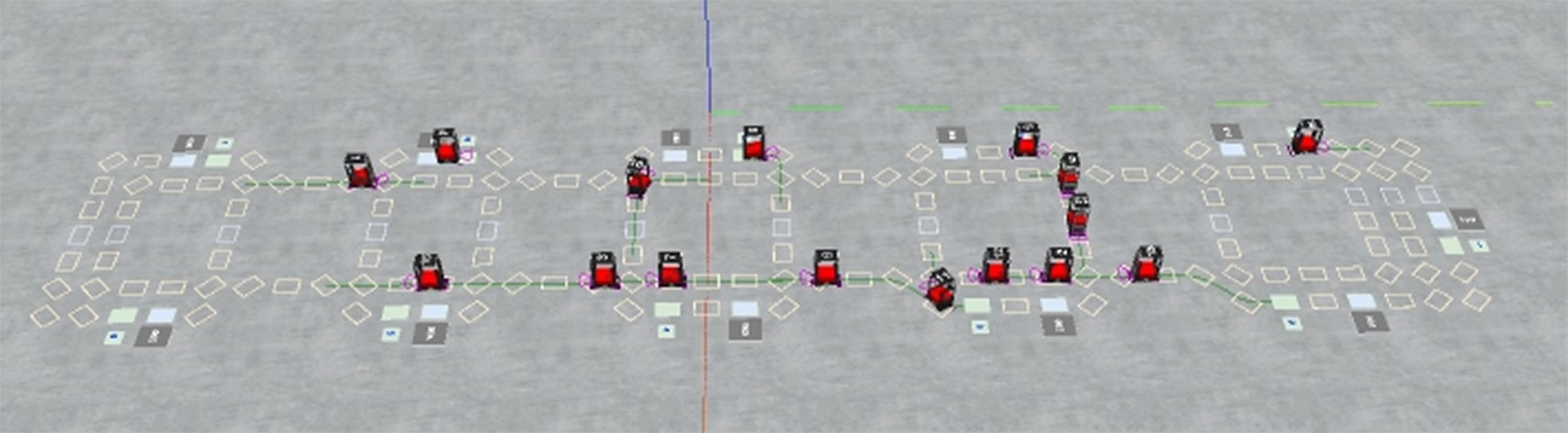

The previous scenarios focused on sorting, but digital twins offer even more possibilities. For example, simulations can test how the available space in a warehouse can be utilized to unlock new efficiency potentials. Companies that work with robots can digitally represent their entire robot fleet and optimize their movements within a facility. When the relevant data is available, delivery vehicles can be included to simulate how goods can be transported between different sorting centers for processing.

A digital representation of the entire operation can concretely influence the physical world and lay the foundation for dynamic sorting and self-organizing logistics. With the virtual counterparts of letters, packages, and pallets, the digital twin can make automated decisions regarding the adjustment of pickups, goods receipts, sorting, and deliveries to optimize the speed, quality, and flexibility of logistics processes. This enables service providers to improve their service while simultaneously reducing operational and investment costs.

A Proven Partner for Digital Twins

At the beginning, it is not entirely easy to reap the benefits of a digital twin. First, it is essential to capture as many physical events as possible using the equipment of the operation. This creates a complete data foundation for accurate predictions. With the captured and stored data, an experienced, competent partner must now translate the customer’s process parameters and factors into functional mathematical models and software. Additionally, an analytical dashboard is needed to present the results.

Prime Vision specializes in creating digital twins from the ground up. The image processing systems, analysis software, data storage solutions, and robotics from Prime Vision are fully integrated into the sorting process and provide the necessary data for precise simulation. The digital twins from Prime Vision are even compatible with products from other providers, ensuring broad coverage. The company specializes in seamlessly integrating its automation products into the existing customer infrastructure.

Prime Vision specializes in creating digital twins from the ground up. The image processing systems, analysis software, data storage solutions, and robotics from Prime Vision are fully integrated into the sorting process and provide the necessary data for precise simulation. The digital twins from Prime Vision are even compatible with products from other providers, ensuring broad coverage. The company specializes in seamlessly integrating its automation products into the existing customer infrastructure.

In any case, Prime Vision can flexibly combine isolated data sources to build a effectively usable digital twin. The research and development team at Prime Vision is capable of translating physical processes into functional software models and delivering an accurate digital representation of individual customer processes. This can be hosted in a customer environment or by Prime Vision, either on-site or in the cloud.

Postal and logistics companies that want to engage in proactive emergency planning need a digital twin for accurate forecasts and decisions. By collaborating with an expert like Prime Vision, these companies can secure their efficiency and future viability – all without the need for clairvoyance.

Alexandra Ballestrem is Key Account Director DACH at Prime Vision

https://www.linkedin.com/in/alexandraballestrem/

https://primevision.com/

Roosmarijn Schopman is Proposition Manager and Lead of Product Management at Prime Vision

https://www.linkedin.com/in/roosmarijn-schopman/

Fotos: © Prime Vision