Logistics Industry Has Information Deficit in Cargo Bicycles

1. October 2024

KION Opens R&D Automation Center EMEA in Antwerp

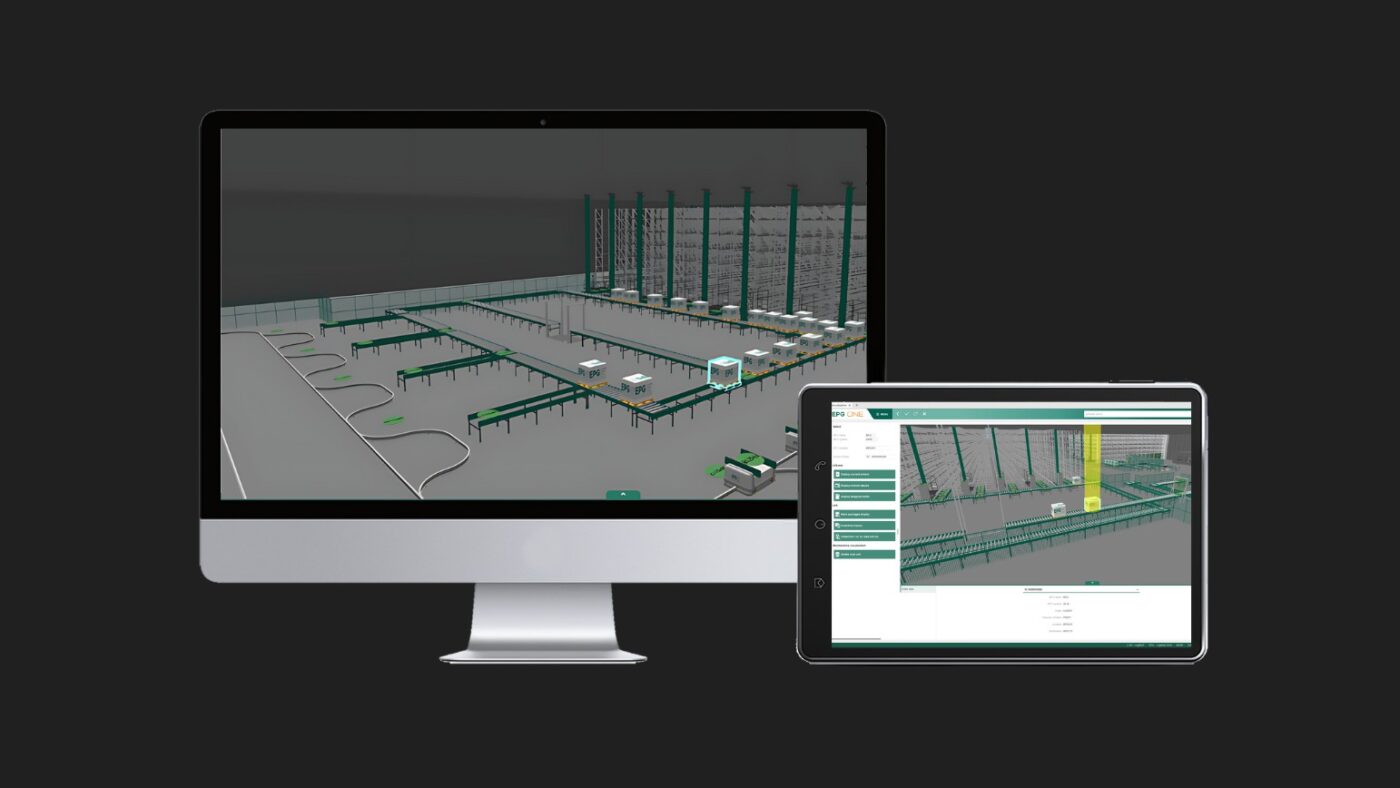

3. October 2024International industry giants such as Bossard, BMW, Misumi, YKK, Fiege, DHL, and Hellmann rely on pioneering technologies for the automation of their logistics processes. A central component of their strategy is the integration of the comprehensive automation solutions of the EPG ONE Supply Chain Execution Suite from EPG (Ehrhardt Partner Group).

(Boppard) With an impressive track record of global success stories in the implementation of highly automated warehouses and the manufacturer-independent integration of material handling systems, EPG has once again established itself as a leading software provider in this segment, ranking first in the global leaderboard. The rapid changes in international markets, coupled with unpredictable fluctuations in demand, personnel shortages, and increasing cost pressures, pose immense challenges for the logistics industry. Geopolitical tensions and trade conflicts exacerbate this pressure, requiring companies to maintain maximum flexibility in their supply chains. Particularly in intralogistics, it is evident that modern automation solutions can successfully meet these demands – from modular warehouse automation systems like AutoStore to Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). A crucial factor for success is the choice of the right software and project partner. Numerous leading companies rely on EPG’s powerful automation software to make their processes future-proof and efficient.

Digital Twins and Global Projects as Pioneers

The Warehouse Control System (WCS) is the heart of this transformation, with which EPG, based on over 35 years of experience in warehouse automation, offers a comprehensive complete solution. This solution manages, controls, and coordinates all aspects of automated material flow and impresses with its manufacturer and hardware independence. This ensures companies maximum flexibility in integrating various automation technologies and providers – today and in the future. EPG relies on cutting-edge technologies, such as the creation of digital twins, to visualize, simulate, or emulate the material flow, including various trades. This digital transformation provides companies with high flexibility in adapting and integrating different systems. An example of this is the global rollout of EPG solutions as part of the BOOST investment program of Bossard AG, which has been implemented in over 40 warehouses worldwide to sustainably increase efficiency and resilience.

Trends in Logistics Automation in 2024

The global efforts are also confirmed by independent market observers. The market research company Gartner predicts that by 2028, around 80% of warehouses and distribution centers will have automation solutions in place. In recent reports, Gartner also emphasizes EPG’s leading position in this significant market segment. According to Gartner, EPG is one of the leading providers of automation solutions and is classified as a global market leader in the area of material handling integration and supportive automation technologies.

The latest trends shaping the industry include the increased use of artificial intelligence (AI) and machine learning to optimize processes and make predictions regarding maintenance and inventory management. Additionally, Autonomous Mobile Robots (AMRs) and Automated Guided Vehicles (AGVs) are causing significant changes in warehouse operations. These technologies help reduce labor costs and increase operational efficiency. By utilizing IoT technologies, warehouses are monitored in real-time, and important data on inventory, transportation, and equipment conditions can be accurately captured.

High Initial Investments and Complexity

Although automation brings many advantages, companies must also tackle challenges such as high initial investments and the complexity of integration. EPG’s solutions focus on scalable and modular systems that allow for a gradual implementation of various technologies, thereby reducing investment risks. This plug-and-play functionality is increasingly appreciated by companies as it enables quick and flexible implementations. At the same time, the manufacturer-neutral integration approach offers high future security for companies.

Future-Proof Solutions for Sustainable Logistics

In addition to efficiency gains and cost savings through automation, sustainability is becoming an increasingly important factor in logistics. EPG solutions support companies’ efforts to improve their CO2 balance. In particular, the use of IoT to monitor energy-intensive automation processes and systems, as well as the integration of “Green Logistics” concepts, are central themes for the future. With over 35 years of experience and a multitude of successful global projects, EPG offers a future-proof and flexible solution for companies looking to meet the growing challenges of modern logistics automation.

Photo: © Ehrhardt Partner Group