Combined Transport Resumes Connection Lübeck – Verona

23. January 2025

BGL condemns threat of price dumping by Mercedes-Benz

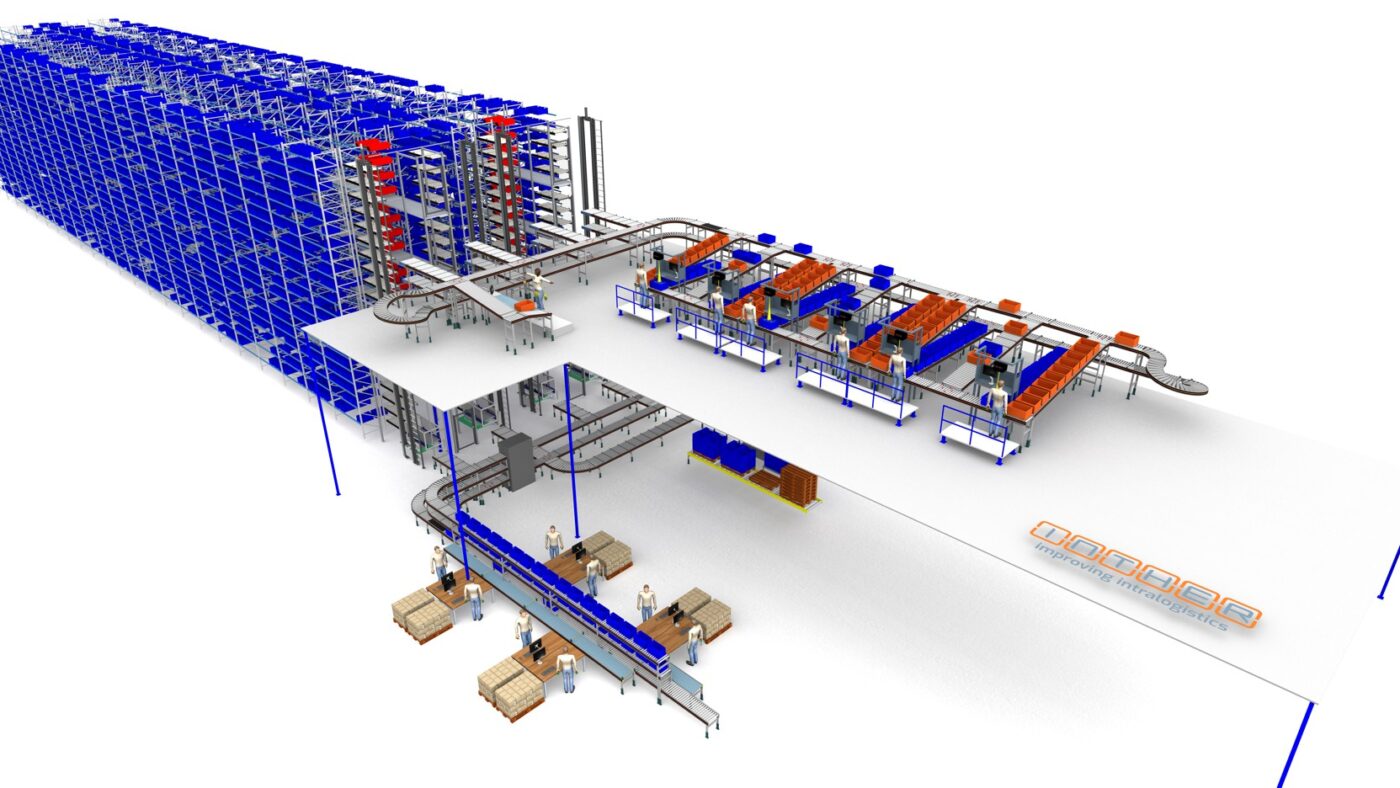

24. January 2025VDL Enabling Technologies Group (VDL ETG), part of the Dutch VDL Groep and a globally active development and production company for components of leading companies in the high-tech industry, has commissioned Inther Group to deliver the intralogistics system for their recently opened warehouse in the XL Business Park in Almelo, Netherlands. Here, VDL ETG plans to centralize their logistics.

(Neckarwestheim) This warehouse will be equipped by Inther Group with an automated logistics system that will be used for the storage and picking of materials for various production sites in the region.

The overall solution at VDL ETG will be controlled by Inther LC software and includes the following components:

- 230 meters of conveyors from Inther Conveyor Equipment

- Two shuttle aisles for a total of 44,000 storage locations

- Six ergonomic goods-to-person workstations

- Mezzanine for goods-to-person operations

- Eight receiving workstations, a palletizing robot, an elevator, and integrated scales

Paul Hermsen – CEO of Inther Group: “Due to our experience and technical knowledge, we initially conducted a thorough analysis to gain a good insight into the project and find the best possible solution. To optimally utilize the entire height of the warehouse at VDL ETG, we will separate the two goods flows on two levels with an additional mezzanine. The inbound/outbound flow contains a loop with six picking stations. The pallet output is equipped with a palletizing robot.”

More than 44,000 Storage Locations

Hermsen continues: “We also use the AS/RS system (with bin containers) as a sequencing buffer for palletizing. We have delivered this before, which is why this project fits perfectly into our portfolio.” Per aisle, we are talking about 35 levels, 13 meters high and 60 meters long, which are also three deep. The system comprises more than 44,000 storage locations in total. “In this way, we were able to consider VDL ETG’s future growth ambitions in the design of the system and make the entire intralogistics system compact enough to allow for several expansions of storage and/or picking capacity in due time,” Hermsen concludes. The goal is to complete the project by the end of 2025.

Photo: © Inther Group