Trigema Increases Efficiency with OHRA Shelving

10. May 2025

Austrian Post Has Ambitious Goals

10. May 2025The southern German family business Metzger Autoteile has commissioned Kardex Mlog as the general contractor for the construction of an automatic five-aisle high-bay warehouse with around 6,000 pallet spaces and an AutoStore system with approximately 80,000 bins. The large project also includes extensive conveyor technology for pallets and containers, several picking workstations, and the complete control of the entire system through the Warehouse Management System Kardex Control Center.

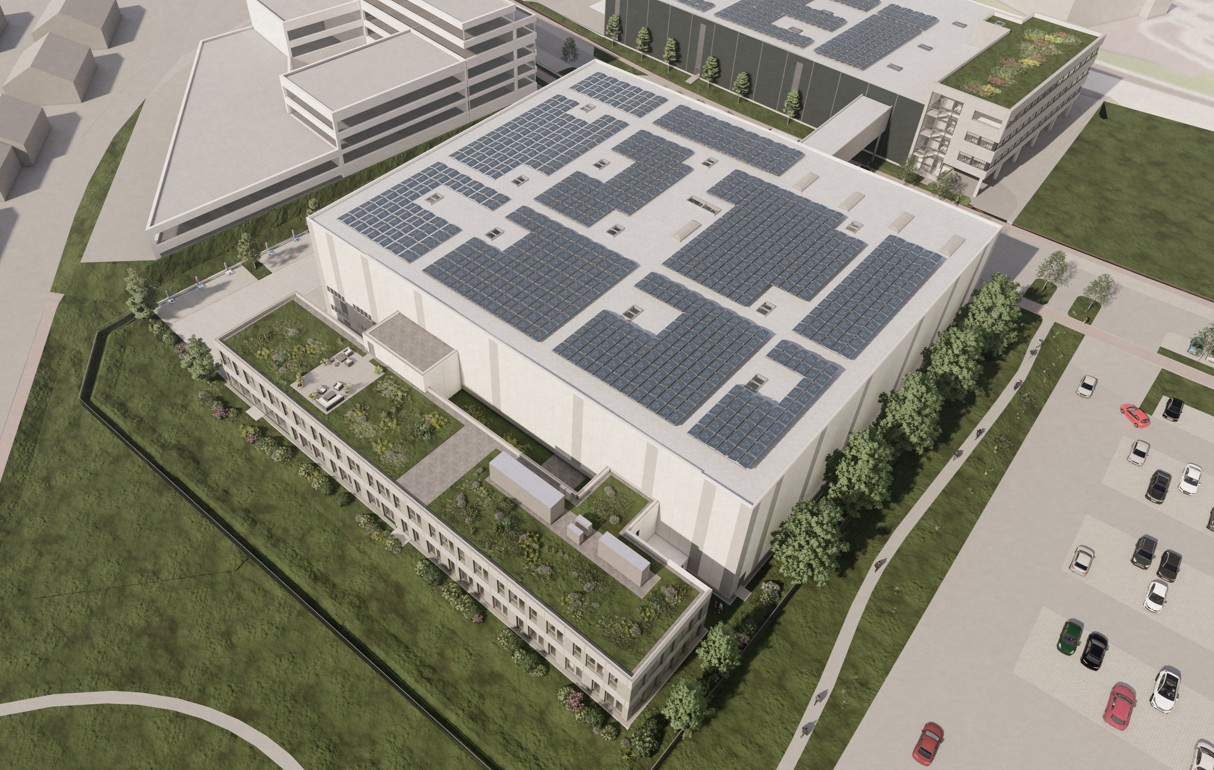

(Neuenstadt am Kocher/Filderstadt) At the customer’s request, the software is to not only manage the new system components but also fully replace the existing inventory system. The concept for the new logistics center was developed by Kardex Mlog in collaboration with Metzger Autoteile. With around 200 employees, the company is already one of the largest employers in Filderstadt. By expanding on a plot of land of approximately 10,000 square meters, Metzger Autoteile is creating additional capacity for further growth. The new logistics center in the Filder-Airport area in Filderstadt is expected to be completed by September 2026.

The Werner Metzger GmbH currently operates a logistics center in Filderstadt that is about six years old. It consists of a manual shelving system, a manual pallet warehouse, and an AutoStore warehouse with about 30,000 bins from another provider.

The delivery scope from Kardex Mlog includes, among other things, five automatic storage and retrieval machines of the type Kardex MSingle A-1000/15-ZT and a shelving system built in-house for approximately 5,860 Euro pallets. Additionally, Kardex will construct another AutoStore system for Werner Metzger GmbH. The grid with a capacity of 77,000 containers will be serviced by 30 AutoStore robots of the type Redline R5. Furthermore, there will be automatic container conveyor technology with a total length of 160m. Kardex Mlog will also establish an automatic pallet conveyor system with 200 drives, two pallet vertical shifters, and six intake and eight discharge points. The delivery scope is complemented by a pallet picking workstation for the replenishment of the AutoStore system. The automated logistics systems will be powered by a photovoltaic large-scale system with a capacity of 500 kWp on the roof of the new buildings.

In addition to the hardware, Kardex Mlog also provides the complete software: The Warehouse Management System Kardex Control Center is designed to manage and visualize in two dimensions the new pallet high-bay warehouse, the expanded AutoStore system, as well as several block storage, wide aisle storage, and shelving storage.

Organizing Deliveries More Efficiently

“With the new logistics center, we can organize the storage and delivery of our products even more efficiently,” explain Marion Metzger and Isabel Brockmann-Metzger, managing directors of Werner Metzger GmbH. “This lays the foundation for us to continue our growth sustainably and to strengthen our market position in the automotive aftermarket further.” The new logistics center also impresses in terms of energy efficiency and sustainability. More than 1,000 square meters of the roof area will be greened.

Photo: © Kardex Mlog