Scannell Properties Develops the Diemelstadt Logistics Park

1. September 2023

CargoBeamer Expands Kaldenkirchen-Domodossola Connection

5. September 2023Can biodegradable sensors and displays be produced using 3D printing? Researchers from the Empa laboratory “Cellulose & Wood Materials” have developed a material based on cellulose that makes this possible. The mixture of hydroxypropyl cellulose, water, carbon nanotubes, and cellulose nanofibers changes color depending on temperature and strain – and all without the addition of pigments.

(Dübendorf) An elastic material that changes color, conducts electricity, can be 3D printed, and is also biodegradable? This is not just a wishful thinking of science: Exactly this “jack of all trades” has been created by Empa researchers from the “Cellulose & Wood Materials” laboratory in Dübendorf based on cellulose and carbon nanotubes.

The researchers used hydroxypropyl cellulose (HPC) as the starting material, which is used as an excipient in pharmaceuticals, cosmetics, and food products. A special feature of HPC is that it forms liquid crystals upon the addition of water. These liquid crystals have a remarkable property: Depending on the crystal structure – which also depends on the HPC concentration – they shimmer in various colors – even though they are actually colorless or pigment-free. This phenomenon is called structural coloration and is known from nature: Peacock feathers, butterfly wings, and the skin of chameleons obtain their colorful appearance not entirely or partially through dyes, but through microscopic structures that “split” the incoming (white) daylight into its spectral colors and reflect only certain wavelengths – in other words: colors.

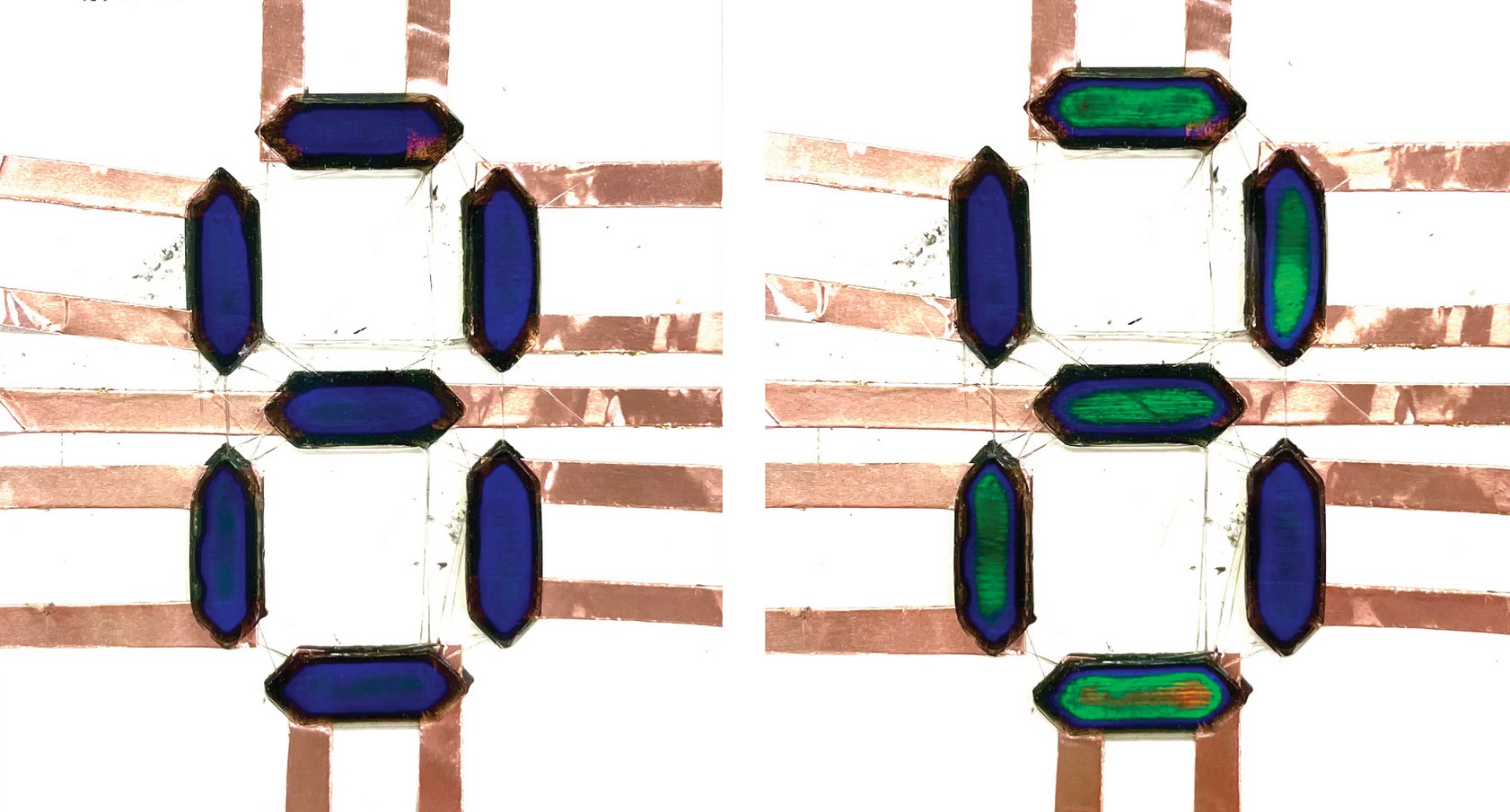

Color also changes with temperature

The structural color of HPC changes not only with concentration but also with temperature. To better utilize this property, researchers led by Gustav Nyström added 0.1 mass percent of carbon nanotubes to the mixture of HPC and water. This makes the liquid electrically conductive and allows the researchers to control the temperature – and thus the color of the liquid crystals – by applying an electric voltage. Bonus: The carbon acts as a broadband absorber, making the colors more intense. With an additional component, a small amount of cellulose nanofibers, Nyström’s team also managed to make the mixture 3D printable without affecting coloration and conductivity.

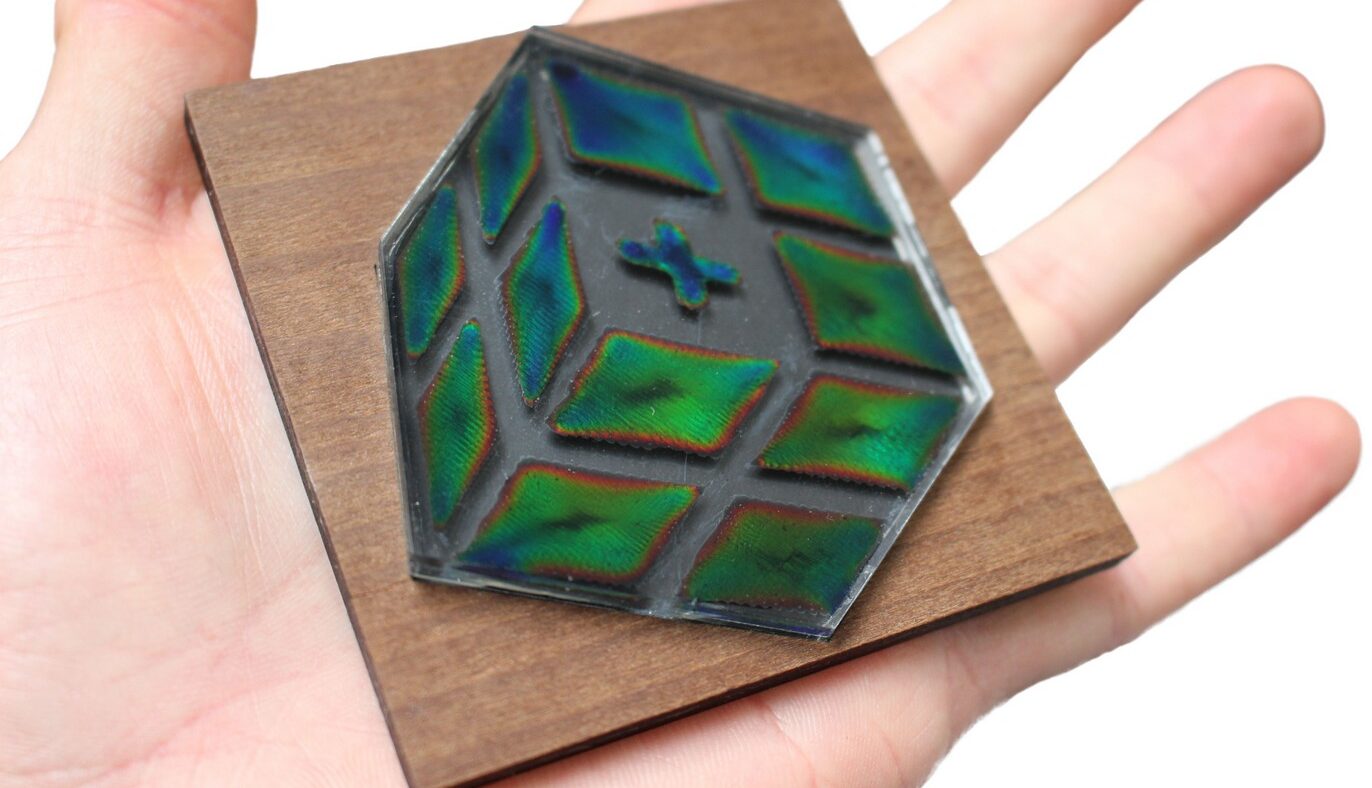

Biodegradable: The display consists of 7 conductive segments that change color through electrical heat

Using 3D printing, the researchers created various application examples from the novel cellulose mixture. Among them is a strain sensor that changes color depending on mechanical deformation, as well as a simple display made of seven electrically controlled segments. “In our laboratory, we have already developed various electronic components based on cellulose, such as batteries and sensors,” says Xavier Aeby, co-author of the study. “This is the first time we have been able to develop a cellulose-based display.”

Various applications conceivable

In the future, cellulose-based ink could find numerous different applications, such as for temperature and deformation sensors, for monitoring food quality, or for biomedical diagnostics. “Sustainable materials that can be 3D printed are of great interest, among other things for applications in biodegradable electronics and for the Internet of Things,” says laboratory director Nyström. “There are still many open questions about how structural coloration arises and how it can be altered by different additives or environmental influences.” Nyström and his team aim to further investigate this in the hope of discovering more interesting phenomena and application possibilities.

Photos: © Empa